Sept. 10-12 Collecting the bread molding recipe:

Table of Contents

From BnF Ms Fr 640

- P029r

STUCCO FOR MOLDINGS

- Have some tragacanth gum and let it dip until it drinks all the water and is swollen and turned into jelly. Then grind it strongly on marble and then have some rye flour which is better than the wheat one for it is more humid and don’t make the batter so dry and spread your tragacanth gum and keep grinding and mingle little by little the very finely sieved flour and knead it as if you wanted to make some bread until you reckon that is thick enough and firm like bread pastry you want to put in the oven. You can reckon when it can be stretched without breaking, and if it is not strong enough it can’t be well detached. After being so prepared, rub it with some cane oil with a brush so the oil soak into it to make it more detachable and press the batter strongly, if it is not well detachable, mix with some flour until it gets thick enough. With this, you can mould very neatly any work or masks or […] You wish which will be dry in one day. Then, apply some white glue or […] glue as you want, and you will be able to paint them, ornate them with gold and other colours. There are used as floor ornaments in Rome and they can be used as bed ornaments. If you to keep your work white, you‘d better mould some plaster rather than flour which is drier and firmer but you have to prepare that way : when it is in powder, soak it in good quantity of water so it is clear and grind it several times a day for 15 days, then pour some water by fits and starts and gather the plaster and finely grind it on marble, and put it in a lead and neat vessel in which mustn’t fall any dust or filth, and leave it still air-dry for a fortnight in its water, And it will become mat and very white and light, very appropriate for a base for brown gold. And this is the powder one you can mingle instead of flour with some tragacanth gum, and your work will be very beautiful. In the absence of plaster, you can mingle some well ground chalk or ceruse and try other similar matters. This tragacanth mingled stucco is typical for fitting on either round or flat things as you wish when it is pressed not completely dried. This is to make some bargain ornaments.

- p140v_b1

- To make a clean cast insulfur, arrange the pith ( soft heart of bread ) of somebreadunder the brazier, as you know how to do. Mold whatever you want & leave it to dry & you will have a very clean work.

- Note: sulfur may have a very low melting point, since I found cast surfer in snow.

p140v_a2 Molding and reducing a big piece

- p140v_b2

- Mold it with the pith of the bread (note: the interior part of the bread) just out of the oven, or like that aforementioned, & and in drying out it will diminish & by consequence so too the medal that you have cast. You can, in this way, in lengthening out or enlarging the imprinted bread, vary the figure & from one face make several quite different ones. Thebreadstraight from the oven is best. And that which has been reheated twice shrinks more. You can castsulfurwithout letting the imprint on thebreaddry, if you want to cast it as large as it is. But, if you want to let it diminish, let it dry either more or less.</ab>

P156r Quickly moulding hollow mould and relief

- Make an impression in colored wax of the relief of your medal. And you will get a hollow mold, in which you can throw en noyau a relief in sand. In this, you will cast your hollow in lead or tin. In this, you you will cast your wax relief.And then on thiswax, you will make your hollow moule en noyau, in order to throw in it the relief ingoldorsilveror any other metal you would like. But to make this process go faster, if you are in a hurry, make the first impression and the first hollow out of the inside portion of thebreadloaf, prepared as you know, and which will cast neatly. And inside this, throw in the meltedwaxwhich will give you a nice relief on which you can make your noyau.

- Question: what is prepare as you know? just from the oven? This shows that using bread in casting should be very common.

- I found this link showing how to use bread to create the hollow for lost-wax casting.

- Since the recipe requires bread just from the oven, we need to bake our sourdough bread.

Sept. 12 11:30 pm, searching for sourdough bread starter.

- We asked around and found that silver moon has sourdough bread starter. Get the information of the owner and Diana contacted the owner via email.

- Meanwhile, Diana started to make her own sourdough starter from the recipe found online.

Sept 13

The owner of silver moon wrote back and is willing to share the starter with us.

Diana started her own sourdough starter and sent some pictures.

Sept. 14 Search for recipe about the knowledge of wax

From BnF Ms Fr 640

p109r_a1 Working in rough with wax

p109r_b1 When the wax is too hard, one mixes in some turpentine or a bit of butter, which renders the wax malleable, and cleaner than tallow, which the Italians mix in, because oftentimes, it is necessary to put the tools into the mouth, [tools] which are better when made from box wood or antler.p109r_a2 Wax for molding

p109r_b2 Since the wax is molten, they have some sulphur in a spoon or crucible and pour it in the molten wax. And with thesulphurgoing to the bottom or staying on top, it stays where it is and mixes only its substance in the wax, and renders it more meltable when warming it, in such a way that having molded it, [the wax] gently melts in the mold like butter, without leaving any blister or boil. Also be warned to not give it too much heat.p109r_a3 Molding wax

p109r_b3 So that your mold takes hold without repelling any surface on a form or figure in wax,it is necessary to rub the wax with oil and soak your sand in lukewarm water, because cold water repels oil even more and will not make a good layer on the wax.

p109r_c3 Rub the oi lon very very lightly, [use] so little that it hardly appears at all. Then rub with some spirits. After soak your sand in lukewarm water so that it does not repel theoil.

p139v_a1 Casting wax to mold an animal that one has not got

p139v_b1a Take some white wax which is much more appropriate for this kind of work than anything else, because it is much firmer and does not leave as much filth, as much as you need to cast the animal that you propose, and no more. And [take] a half quantity of ground coal and neatly sieved through a cloth or coal sleeve, using it to give some color to your wax, that would otherwise be transparent and you will not be able to see your lines as clearly. Put your wax on the coal fire to melt. And when it is well-melted and well-liquified, take a full eared-porringer of melted wax, [and] as much sulphur as the amount of a large pulverized walnut. Melt all of over a slow fire and when it is melted, do not leave it on the fire because it will become too hot. But take it off and keep stirring it with a little stick and when it has finished bubbling and is as liquified as water, cast it into the wax that you will have previously removed from the fire. And mix and stir both of the them so that they join together. After stir in little by little while continuously mixing, the charcoal that has been repeatedly ground, and in this way it will be very well incorporated. This is how you will know that your wax has gone beyond its ideal heating point, it will release no more smoke, it will start to have lines appearing on the side and not in the middle, and those lines will be close to each other. If you cast too hot, you will not be able to separate your wax from your mold and it would stick to the cast. When it is at the right state, stir it with a little stick so that the pulverized charcoal is well mixed in and has not fallen to the bottom of the mixture. And in this way, throw it in your mold bit by bit and not in one go, because wax is not runny.</ab>p139v_c1a This black sulphured wax is for fashioning round figures that do not come out of the mold. And they need to be burned in the moule au noyau rather than be opened like the ones that have something jutting out or an intertwining of legs and arms. And this wax, thanks to the sulphur,will melt with little heat and leave without leaving any filth. If by some misfortune the crushed charcoal remains in ashes, when you open the mold and blow on it, it will come clean.</note>

p139v_c1b To make wax serpents or other things to affix to candles, it is necessary to cast them with esbaucher wax of all colors.

p125v_b3a

When you want to cast in wax in a plaster mold, you must know this secret, that there is need that your mold be in hot water. The animal will never come out as clean as in metal, because wax grips. But to rough out an animal as close to natural as possible in order to fix it afterwards, you have to remove all the scales, because the wax will permeate them & will not be able to be stripped off. In molding the animal, take off the scales for wax, but on the contrary [when not molding with wax] rub them against their grain so that they raise up, because then these animals [sc. those not molded in wax and prepared in this way] will show better. Do not wait to strip off your wax until it is cooled down at all. But while it is a bit hot, after you have molded the first casting of the animal, uncover it halfway so that it be stripped in so doing. And having as much in one mold as in the other, make very many large castings holding on to the animal in order to fortify them [...] stripping, & afterwards you’ll cut it.p133r_a1 Hard wax to imprinting seals

<ab id=“p133r_b1”>One makes these [seals] out of white wax which is harder than the other and one mixes in it some cerussite or leaded white very finely ground such that it is as hard as you like and mix in a drop of turpentine to bind it. Afterwards mix it in the color that you want. It is in wax that goldsmiths start.</ab>

Knowledge about molding sulfur

From BnF Ms Fr 640

p012r_a1 Molding sulfur

p012r_b1” Sulfur is improved by mixing in soot black or powdered sanguine, which makes it harder and more resistant, after letting it melt entirely until it becomes liquid and similar to oil. Mixing it with verdigris, you can use it for casting a lizard or something else in plaster, very cleanly.p012r_c1

You must not cast it until it has quite down and lost all its bubbles and eyes, and its surface has fallen and become flat as water. Soot black gives it a fine luster and makes it neater. Useyellow sulfurof the best kind, as the greyish natural sulfur is no good. Don’t cast it in the wind and cold for it would fill with bubbles.September 18, 2014

Diana Mellon, Michelle Lee, Yijun Wang

Bread Molding Recipe, bread-making

two main sources:

- Jacob Burton's recipe for sourdough bread: https://www.youtube.com/watch?v=YfWcs2k7oQ4

* 275g Warm Water

* 500g Poolish Sourdough Starter

* 400g Bread Flour

* 100g Whole Wheat Flour

* 20g Salt

- Robert Godfrey’s receipts, 1665-1799 from U of Iowa DIY site:http://diyhistory.lib.uiowa.edu/transcribe/scripto/transcribe/1800/56904

“To make French Bread. Take a quantity of the finest flower you can gett and mingle it with milk and water of equall quantity and double the quantity of yest wch is used to be put in other manchett and mingle it so stiffer then you use to mingle it for a puddinge it must be laid in dry flower the space of 6 houres where it may be kept warme the oven must be hotter then for other manches then rowle it up in flower and put it in little dishes then put it quickly out of the dishes uppon the peele and put it in the oven quick it must stand 3 quarters of an houre it will rase best when it is hott yff hee puts salt in the bread it wilbe the heavier.” (p. 33)

both ended up being very similar in general, though described very differently! Since the Godfrey’s one didn’t mention the ratio and the measurement, we used the Burton’s.

our procedure

- converted grams to cups based on the information on King Authur’s website http://www.kingarthurflour.com/recipes/extra-tangy-sourdough-bread-recipe

- just over 2 cups starter (we used Silver Moon's rye/all-purpose starter)

- 1.2 cups water

- 4.2 cups flour (Bob’s Red Mill stone ground organic whole wheat)

- hand mixed all together in ceramic bowl

- dough remained sticky, became less sticky at the end

- 2:00 left to rise under wet cotton kitchen cloth (to keep in moisture)

- 5:45 dough has risen to not quite double its original size

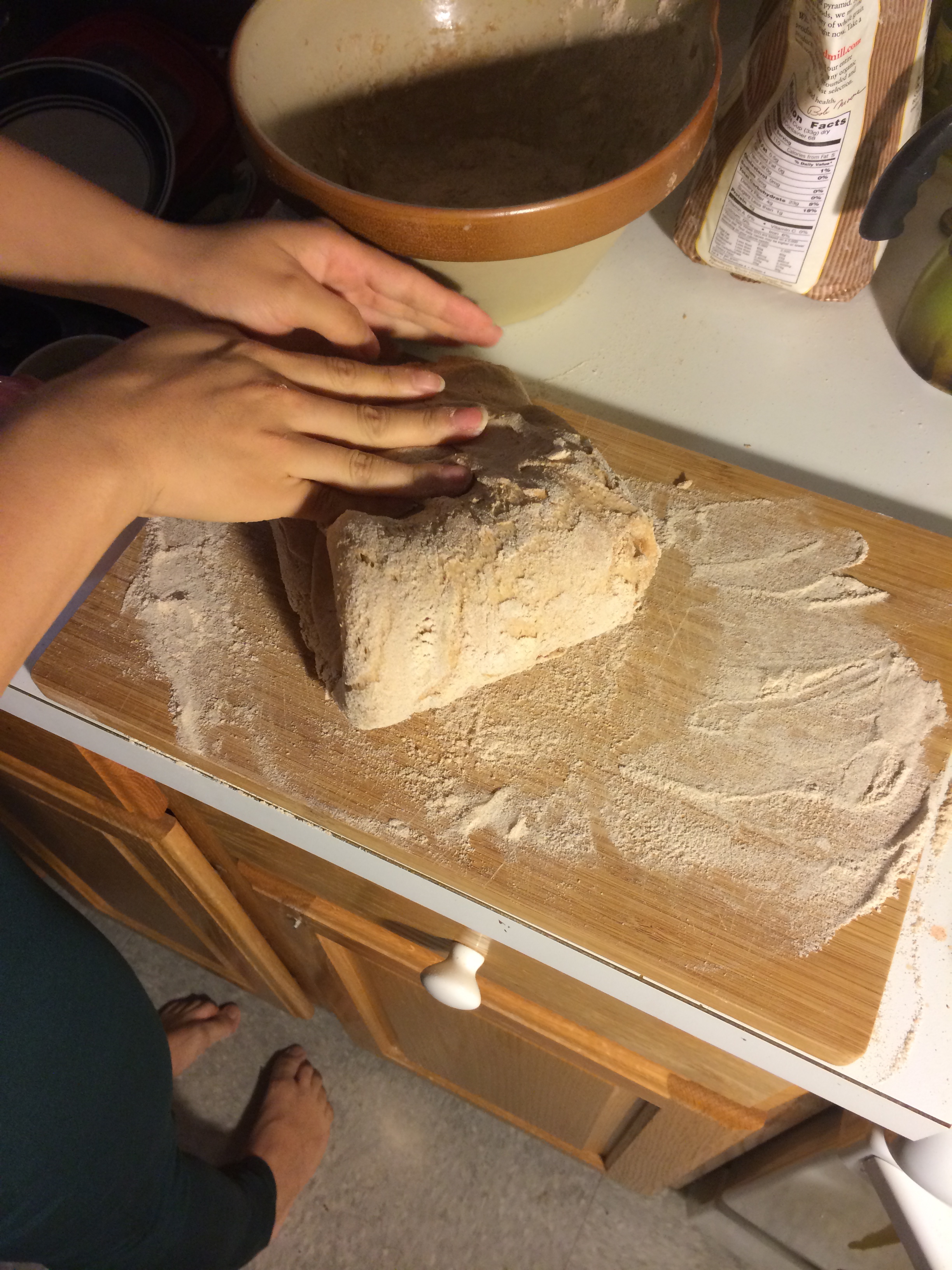

- kneaded dough on wooden board

- dough feels less sticky at first, then becomes stickier

- dusted wooden board and bread lightly with flour

- slightly more elastic than early afternoon

- folded bread over, placed back into ceramic bowl dusted with flour, seam-side up

- 6:00 left to rise under wet cotton kitchen cloth

- 9:45 dough has risen to double its original size

- dusted wooden board with flour and began kneading

- contains air pockets and reduces when kneaded

- more elastic, can be folded without breaking, sticks to itself better

- surface feels and appears drier

- folded bread and shaped it seam-side down into round

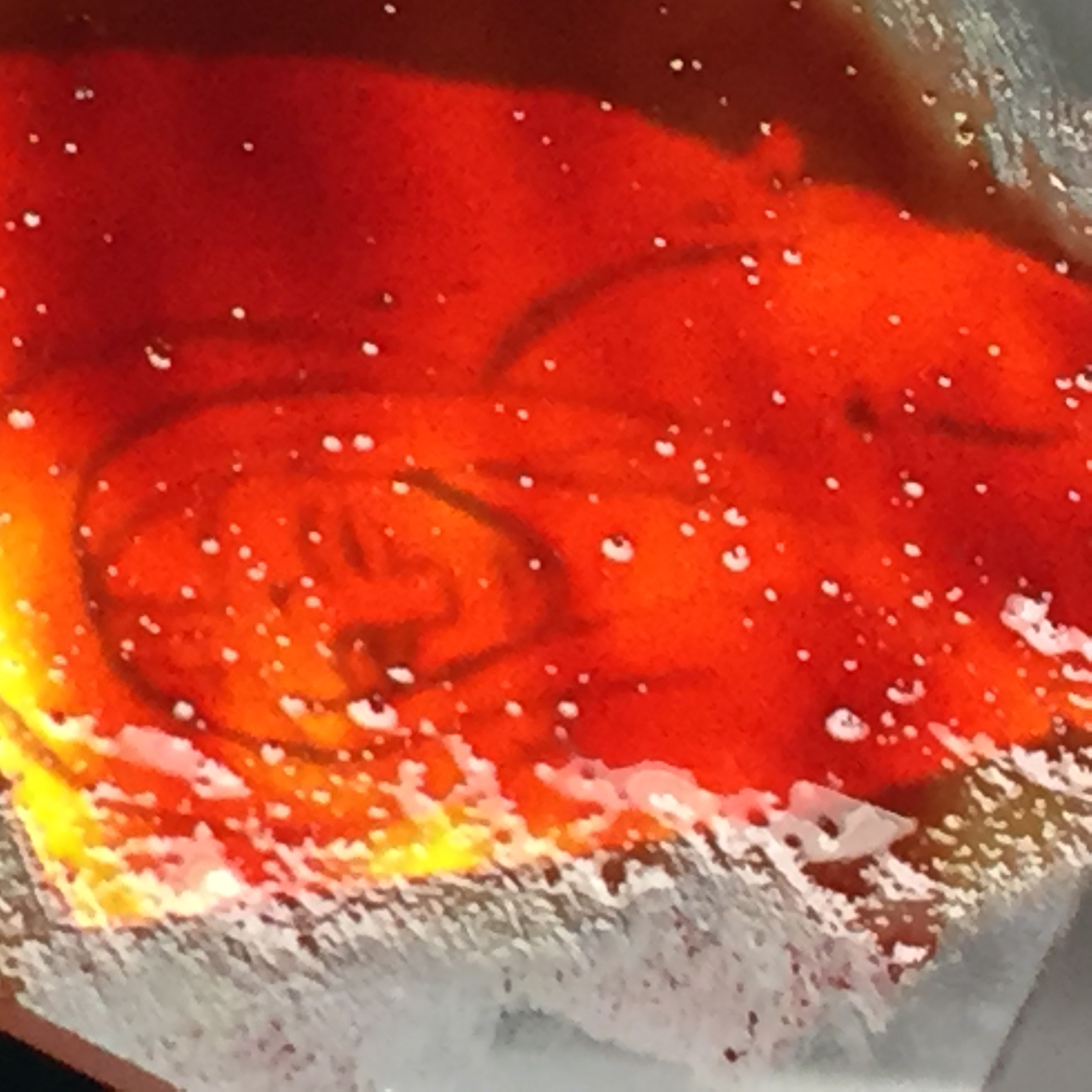

- 9:58 placed bread in oven at 500 F in cast iron enameled Dutch oven with lid on

- 10:10 removed lid, turned head down to 425 F

- 10:30 checked on bread

- nice crust is building!

- inserted knife, found center still raw

- replaced bread in oven

- 10:45 checked on bread

- similar, crust more browned and crispier

- inserted knife, found center to be less raw, but still raw at deepest level

- replaced bread in oven

- 10:53 removed bread from oven

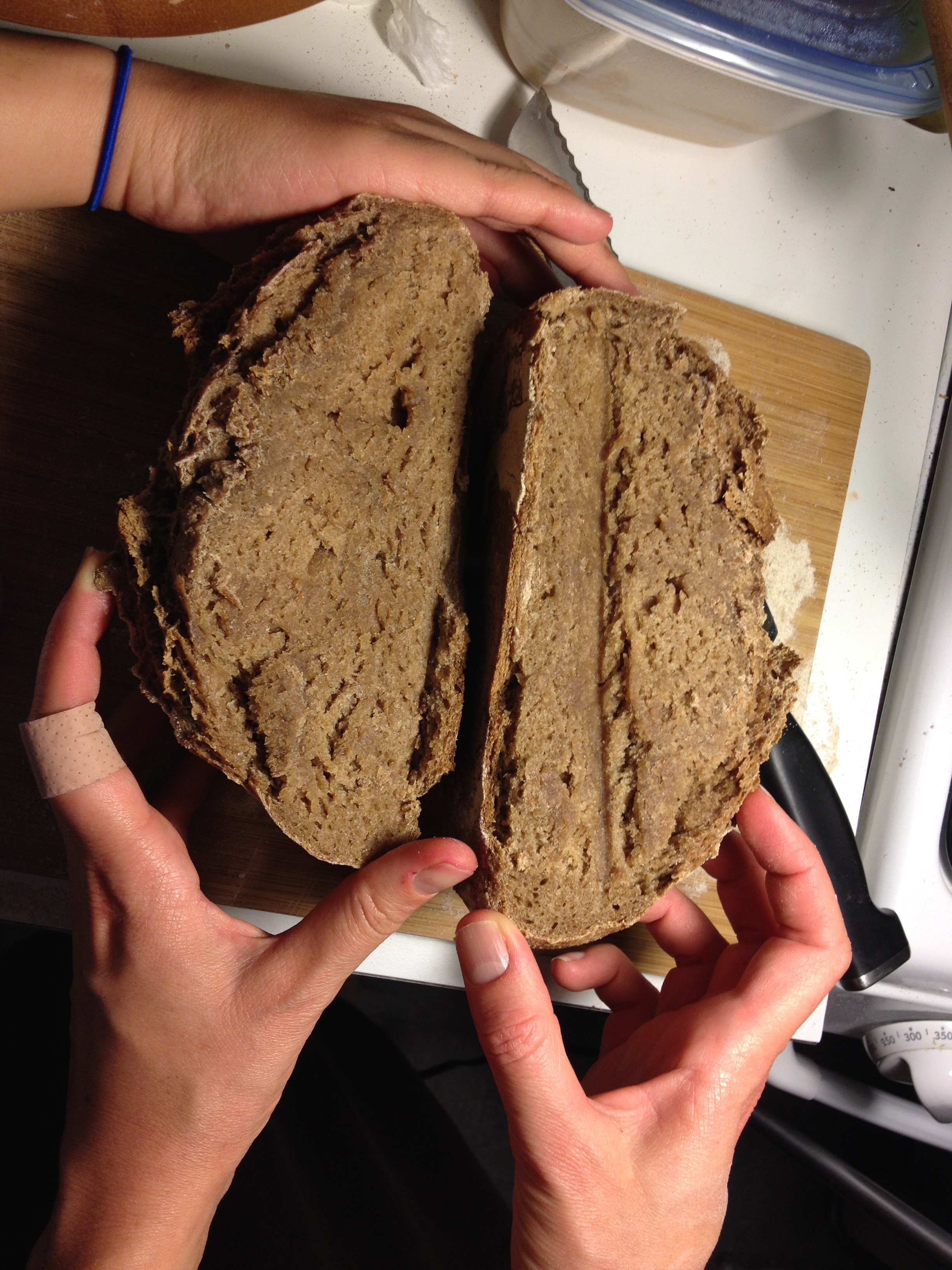

- sliced bread in half — steam comes out!

- inside appears uniformly brown and dense, slightly moist, very hot

- scooped dough out of two halves of crust with spoons

- shaped dough mass around 3 objects: seashell, fish-shaped bottle opener, small scissors

- pressed objects firmly into dough and left on wooden boards to harden

- ate remaining crust: delicious! (especially with cheese)

- a challenge: bread emerged from oven very hot, making it difficulty for us to mold by hand before it hardened

- the bread began hardening quickly so we just worked through the heat!

- success?! TBD...

•Sept. 29 Molding Sulfur Recipes

- <title id=”p012r_a1”>Molding sulfur</title>

<ab id=”p012r_b1”>Sulfur is improved by mixing in soot black or powdered sanguine, which makes it harder and more resistant, after letting it melt entirely until it becomes liquid and similar to oil. Mixing it with verdigris, you can use it for casting a lizard or something else in plaster, very cleanly.</ab>

<note id=”p012r_c1”>You must not cast it until it has quite down and lost all its bubbles and eyes, and its surface has fallen and become flat as water. Soot black gives it a fine luster and makes it neater. Use yellow sulfur of the best kind, as the greyish natural sulfur is no good. Don’t cast it in the wind and cold for it would fill with bubbles.</note>

- <title id=“p140v_a1”>To cast in sulfur</title>

<ab id=“p140v_b1”>

To make a clean cast in sulfur, arrange the pith of some bread under the brazier, as you know how to do. Mold whatever you want & leave it to dry & you will have a very clean work.</ab>

<note id=“p140v_c1”>

Try sulfur passed through melted wax, since it won’t catch fire & won’t make more little eyes.</note>

- <title id=”p043r_a3”>Purpurine</title>

<ab id=”p043r_b3”>Take half an ounce of soft tin, melt it in a spoon. Once it is melted, throw in an ℥ of ☿, mix together. Once they are cold, grind on a porphyry slab. Then take an ℥ of sal ammoniac and an ℥ of the yellowest sulfur that may be found, grind both. And then mix very well all the aforementioned materials. Then put all together into a glasssublimatorium. Hold this over a small fire for an hour, and for an hour over a stronger fire, and for an hour over a very strong fire, and it will be ready. Then, to use it, apply resin black with the glue used by painters to paint, two or three times, until it is quite black. Then apply a bit of varnish. Once it is dry, apply the purpurine dry with a finger where you want. The more you apply, the finer it will look. Then, if you like, you can apply varnish on top.</ab>

DELIGHT IN GROTTOES (art/nature orientation)

(there are many more references to grottoes throughout the ms.)

- <title id=“p118r_a3”>For grottoes</title>

<ab id=“p118r_b3”>Stones made from water called [stuf]. Charcoal, the work of tin, and pure brass. Paper ground up and mixed with ground up glass. Cork. Heated parchment, white coral. All of them are appropriate for making grottoes. But, once dry, bizarre pieces of wood, which are found in the forests and among [regular] mushrooms and large mushrooms [growing on] trees, are better than all of them because they are light. Mix in with small pieces of looking-glass tin which have a shiny luster. Grind in a little [bit] of a different kind of marcasite in order to clean the earth away, then powder the work, which is very beautiful. If there is no spring in the grotto, glue all of this with strong glue, and then the work is done. You must show all kinds of mines. The sulfurous marcasites which do not have a grain but are even like looking-glass tin are very beautiful.</ab>

Sept. 29 Pouring wax into bread mold

NAME: Yijun WangDATE AND TIME: Sept. 14, 2014 9:00-11:00 AM

LOCATION: Columbia University, Chandler Hall Rm. 260 - Manhattan, NY

SUBJECT: Cast wax in breadmold

l Only two of our mold left. The fish one broke.

l Prof. Smith heated the 100% beeswax on an electronic stove with a pan with enamel surface

l We poured wax into our breadmold

n The scissor mold turned out to be leaking. Diana built a wall with wax to prevent leaking

n The shell mold was leaking too since there was cracks on the bottom. We couldn’t really fill the mold full with wax.

RESULT DISCUSSION

l Our bread mold was not so successful

l The cracks in the bread turned out to be the reason for leaking. The cracks started to appear since the bread was dried out. So probably the bread should be fresh when used for making molds.

l We shouldn’t get the inside part out and remake it a flatter surface. This action also caused cracks. We should cut the bread directly and cast/press the metal at the beginning.

l Other groups working with white bread had better results. So whole wheat may not be a good choice.